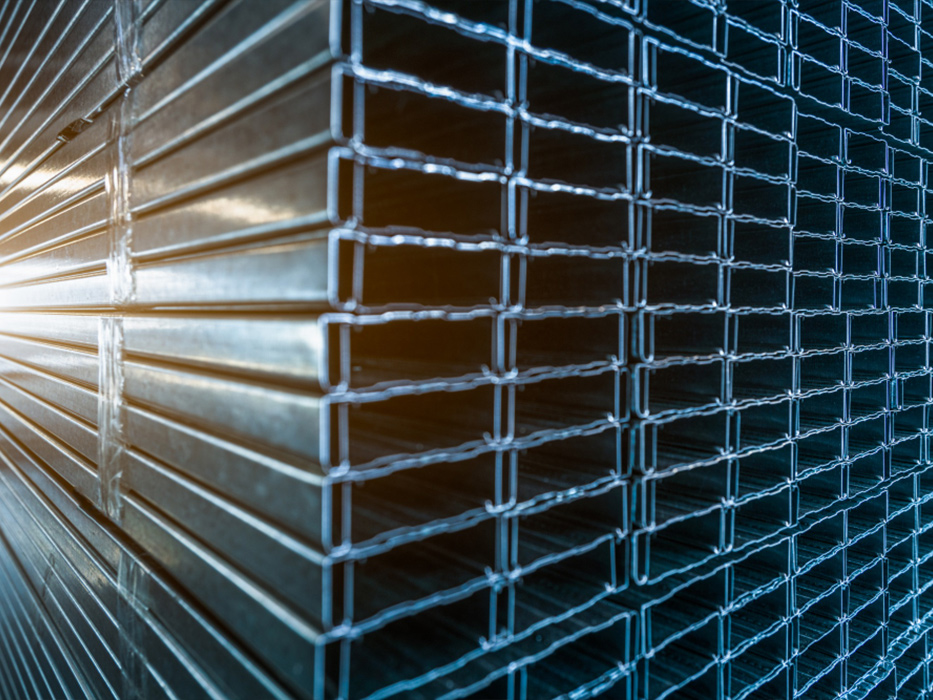

I-THANA TYPE C PURLINES

Excellent Characteristic of Galvanized Steel

Corrosion resistance

Galvanized process is for the protecting the oxidation on Steel’s surface. Furthermore, Galvanized is also shown the excellent characteristic for protecting the Sacrificial corrosion by replace the oxidation for steel. This is the reason for protecting the rust at the edge or surface which’s the position to occur the corrosion condition.

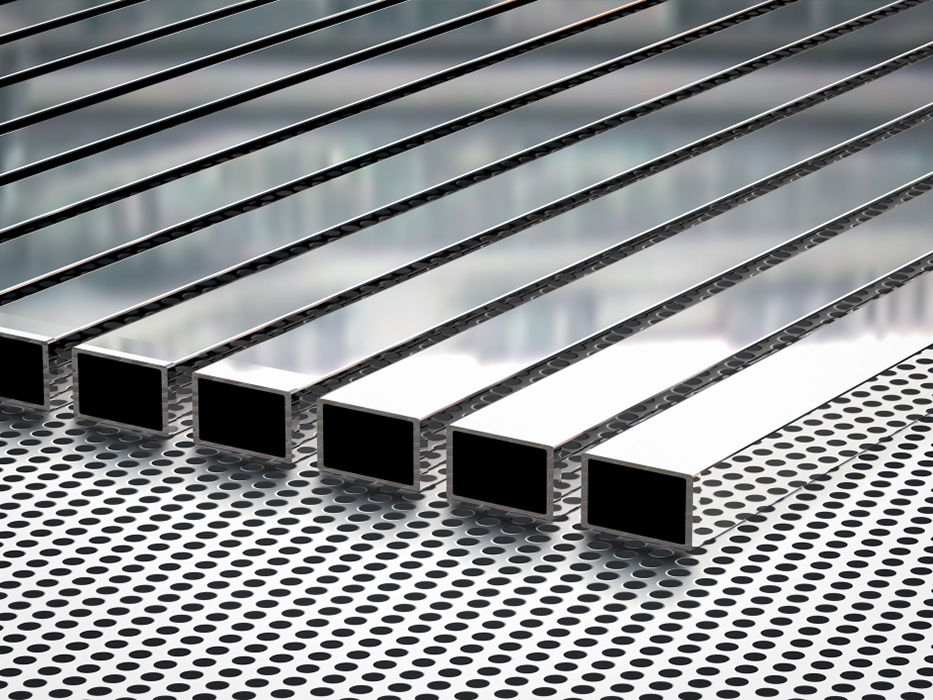

Forming process

Galvanized Steel product of I-THANA has been passed the Galvanized coating process that’s called “continuous Hot Dipping Process”. This process give the good quality of coating, durability, no crack or peel off during compression process and forming process.

Welding process

Galvanized Coated Metal product of I-THANA can be welded by various method such as Voltage welding, Brass-Lead welding, Single Spot projection welding, Seam welding and Knot welding.

Product Features:

Type C Purlin steel, the product under I-THANA brand, that’s used for the part of building make from the high steel base on yield strength 450MPa(G450) and Galvanized for rust protection. When compare with the general steel in the market, Type C Purlin steel, the product of I-THANA is very efficiency on the durability.

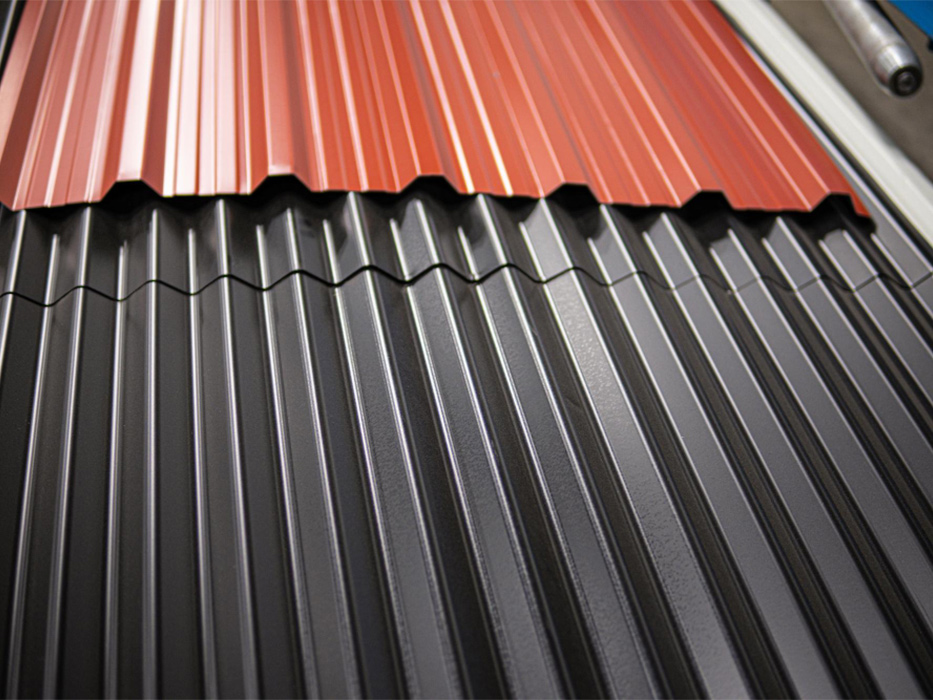

Type C Purlins can be use for the Roofing and Sliding/Wall

- Cost saving and reduce the step of color making

- High steel G450

- Galvanized for rust protection, reduce the step of color making, protect the welding line

- Electric cost saving on the welding process for Type C Purlins, Durability and Force supporting

- Light weight, Reasonable for archtitecural

- Long life property

- Excellent for rust protection with out the color coating

- Easy to installation same as general steel